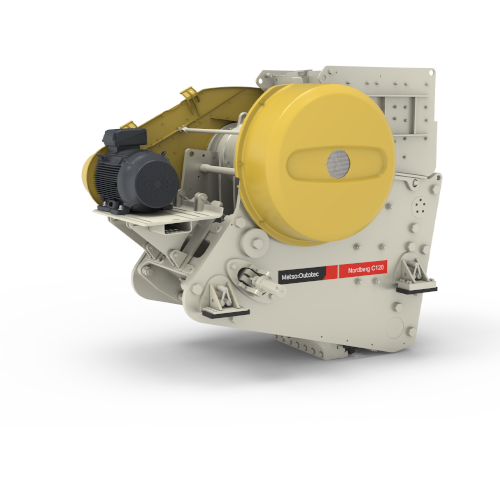

Jaw crushers Nordberg® C Series™

Nordberg® C Series™ jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications.

They have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials. The product family consist of models of different sizes that are engineered to deliver the maximum productivity at the lowest operating costs.

The product family consist of models of different sizes that are engineered to deliver the maximum productivity at the lowest operating costs.

To producer’s siteThe core of Nordberg® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. Nordberg® C Series™ jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity.

A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher’s cavity without restrictions. A steeper nip angle decreases operating costs by reducing wear on jaw dies and speeds up material flow down in the cavity. The stroke is amplified from top to bottom, leading it being longest in the bottom of the cavity. This increases the capacity as well as the reduction ratio, resulting in high production in all kinds of operations.

Detailed technical specification can be found on the manufacturer’s website if you follow the link on this page.