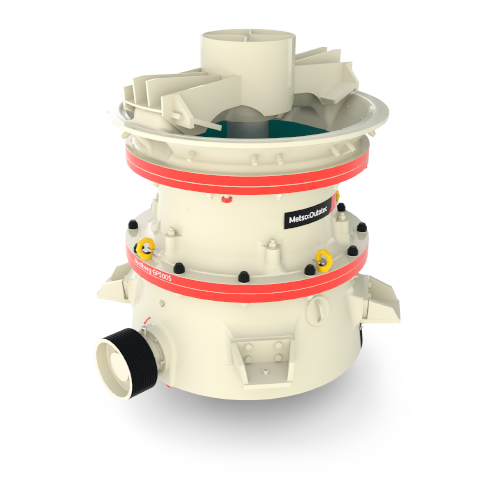

Nordberg® GP Series™ Cone crushers

Nordberg® GP Series™ cone crushers have been developed to crush feed materials into desired end products efficiently, reliably, and economically.

Engineered for all rock types, these machines can be utilized as secondary, tertiary, and quaternary crushers in aggregates production plants and in mining operations.

To producer’s siteNordberg® GP™ cone crushers are an excellent choice whenever high reduction, first-class cubicity or great capacity is required.

The optimized design of the castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter. Cavity designs provide maximum yields for required high-quality end products. The stroke and cavity change feature allows crusher throughput to be easily adjusted to work in harmony with the rest of the crushing plant.

Nordberg® GP Series™ cone crushers can be adapted to any specific production requirements with adjustments such as change of cavities, eccentric strokes, counter shaft speeds and different control methods. The stroke change feature allows crusher throughput to be easily adjusted to work in harmony with the rest of the crushing plant. The adjustable stroke also allows you to attain proper choke feed conditions and optimum crusher settings, ensuring the maximum yield of a required end-product size.

The crusher automation, on the other hand, provides smooth process adaptation, full crushing process automation, and ensures that your crushing machine runs at its optimal performance level.

Detailed technical specification can be found on the manufacturer’s website if you follow the link on this page.